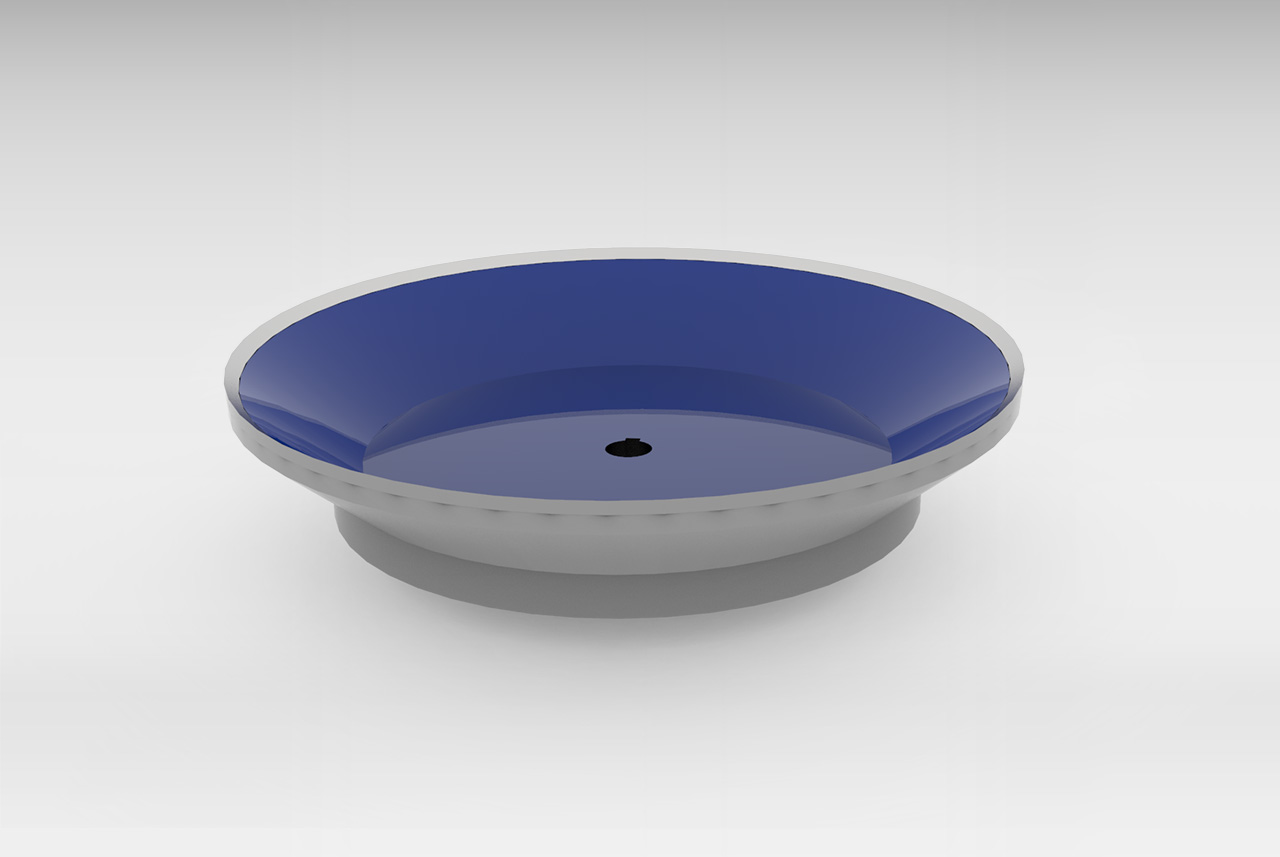

Rotors with PU coating (for coating and, to some extent, for pelleting)

- For utilisation of the maximum batch volume

- Optimal seed mixing

- Greatest possible speed during secondary distribution

- Ideal for large series (less frequent changing of applied product)

- For very smooth seed (e.g., wheat, beans, maize, etc.)

Rotors with chromium coating (for pelleting and coating)

- Optimal for seed pelleting

- Better mixing than with ECTFE coating

- Maximum batch volume and mixing intensity cannot be reached during coating

- Durable (high wear resistance)

- Easy to clean

Rotors with ECTFE coating – special model (for pelleting and coating)

- For smaller volumes

- Ideal for small series (frequent product change)

- Less service life than chromium coating

- Easier to clean than PU and chromium coating

- Maximum batch volume and mixing intensity cannot be reached during coating