The machine to fit the customer – not vice versa

Many different issues are associated with the encrusting and pelleting of seed – and there are just as many possibilities for technical realisation.

This is why our product portfolio includes both standard and specialised machines

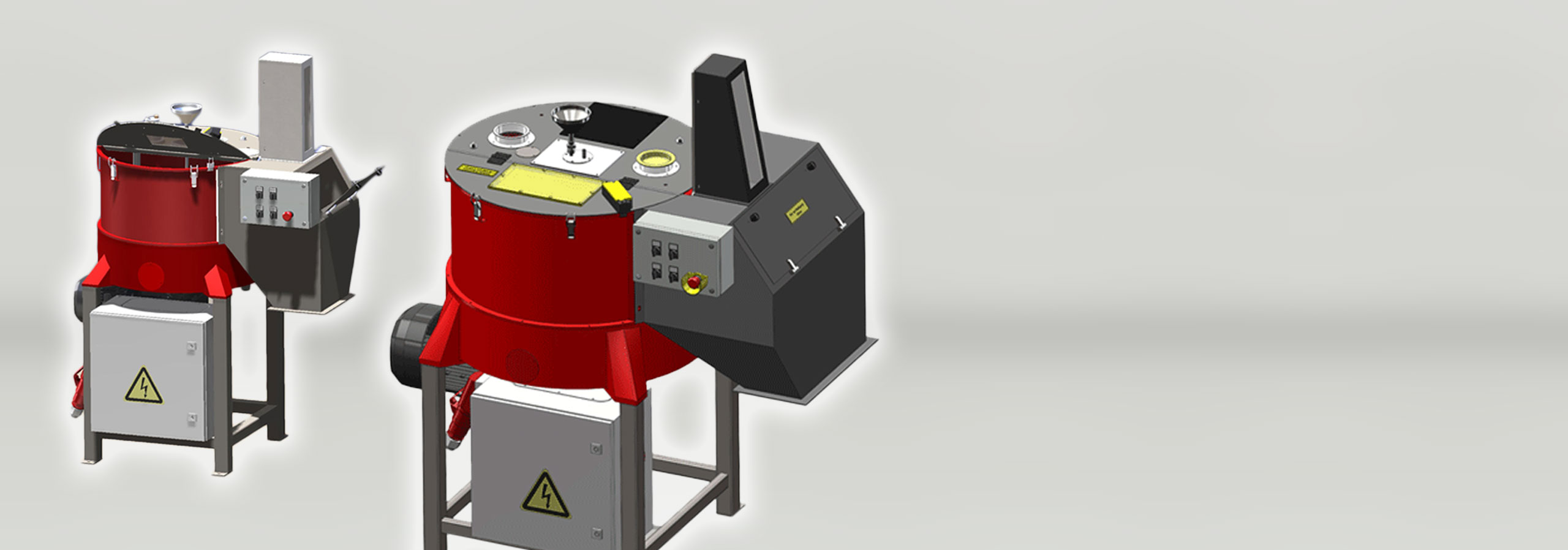

Our range of standard machines comprises seed coating machines for small quantities (e.g. in the laboratory) together with machines for medium-size quantities and large-scale production.

The mixing chambers are available in 8 sizes:

for batches up to 0,05 dm3, 0,1 dm3, 2,5 dm3, 12,5 dm3, 32,5 dm3, 65 dm3, 130 dm3 and 180 dm3.

On the basis of these mixing chambers we design seed coating machines with exactly the required output and configuration to match the customer’s particular needs.

All our seed coating and seed pelleting machines are “Made in Germany”

From drawing-board and assembly line to software development and programming – our machines are produced entirely in our Elmshorn works.

Hardware and software from a single source – and with a single responsibility

Intelligent SATEC system controllers => Less work for your personnel + Prevention of faulty batches

Rotor-stator mixing principle

Our coating machines are all based on the rotor-stator mixing principle and can be used not only for the coating, encrusting and pelleting of seed but also for many other purposes (e.g. for fertiliser granulating, or for applying rodenticides to substrates).

Our coating machines are all based on the rotor-stator mixing principle and can be used not only for the coating, encrusting and pelleting of seed but also for many other purposes (e.g. for fertiliser granulating, or for applying rodenticides to substrates).

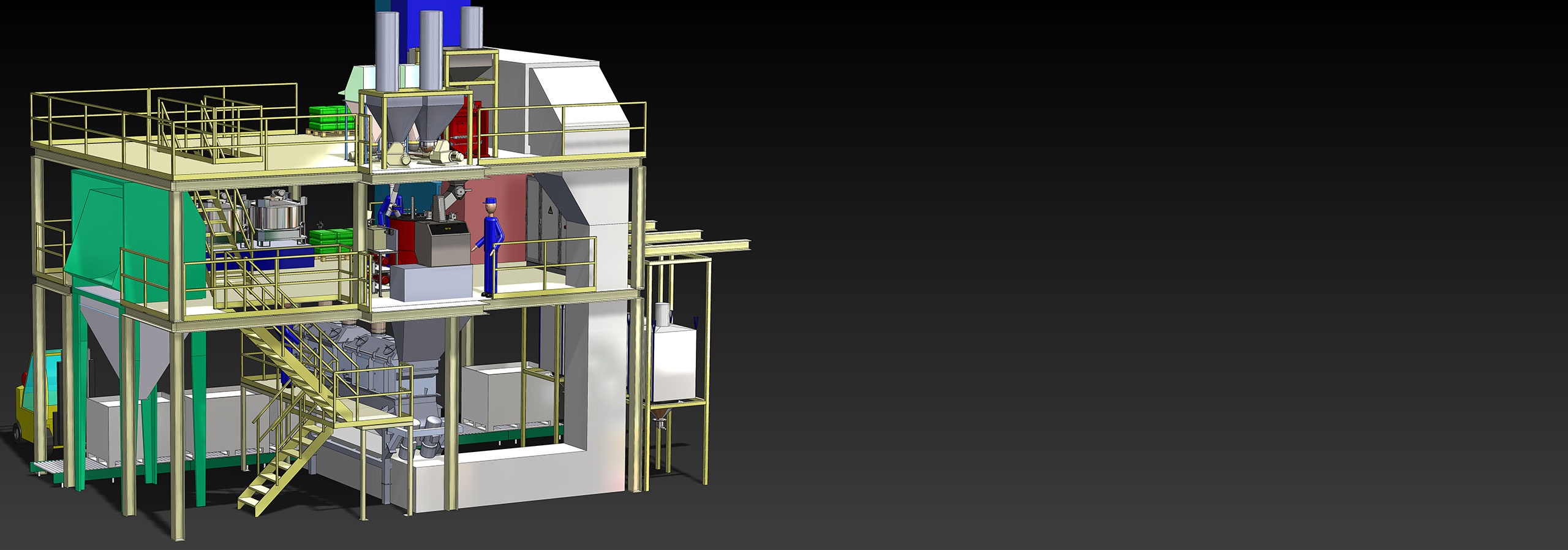

SATEC CONCEPT – A single process from trial seed to large-scale production

The SATEC CONCEPT batch coater offers clear advantages:

- accurate dosing of seed and dressing

- homogeneous distribution at all throughput rates

- no startup or shutdown losses

- exactly preselectable amounts of treated, whether 5 kg, 330 kg or 30 t

- shortest possible cleaning time when changing over to different seed varieties

- modular construction allowing a wide range of additional equipment to be fitted as required

- internal data management and recording

- online assistance and diagnosis, software updates

Click HERE to find out more about the rotor-stator mixing principle.